Project Description

Introduction of

Automatic Dual-face Spot Welding Machine

Automatic dual-face spot welding machine works as a high-speed spot welder to weld nickel plates onto positive or negative ends of cylindrical lithium-ion cells, so that you could get desired serial connection and parallel connection on a group of cylindrical li-ion cells.

This automatic dual-face spot welding machine is pneumatically driven so that the contact pressure on each welding point is consistent. By applying constant pulse current, this machine can ensure consistant welding quality on all welding points, and this is very critical for the quality and reliability of a finished lithium-ion battery pack.

This automatic dual-face spot welding machine has very high welding efficiency. And it’s very easy to change the fixture and parameters when you need to weld another pattern of lithium-ion battery packs. Moreover, it does not only support dual-face welding operation simultaneously according to set data, but also can be set to weld at one face only. In another word, it gives flexibility to fit changing demands in real lithium-ion battery production process.

Technical Specification

Input voltage: AC200V~265V, 50Hz (Note: Other voltages can be customized.)

Max. power consumption: 6KW

Pneumatic Pressure: 0.4-0.8Mpa (Note: Filtering device must be deployed to ensure there is no water or dust in the air supply. )

Max. welding distance: 620mm x 320mm

Applicable cells: Cylindrical lithium-ion cells like 18650, 26650, 21700, 32650…etc. (Note: Customized solution is also available for spot welding demands for lithium polymer batteries, or for connection between cells and BMS.)

Applicable nickel plate: pre-cut nickel plate, with 0.1-0.3mm thickness. (Note: Nickel plate with 0.21-0.3mm thickness need be notched before use. )

Data input method: Array input, Point input, U disk input

Welding effect: min. 4KG tension for 0.1-0.125mm thick nickel plate

min. 6KG tension for 0.15mm thick nickel plate

min. 8KG tension for 0.2mm thick nickel plate

min. 12KG tension for 0.3mm thick nickel plate

Productivity: about 2800 ~ 3300 cells/hour

Product dimension: 1630 x 850 x 1630mm

Net Weight: about 220kgs

Machine Features

Reliable framework & protected cabinet to ensure stability and safety during welding

Even, consistent and neat welding points, very good consistency

High welding efficiency, suitable for mass production of battery packs

Support multiple data input methods, capable of handling changing demands in real lithium-ion battery production process

Capable of saving up to 199 sets of data, easy and fast to switch models in production

Simple and easy to operate and maintain

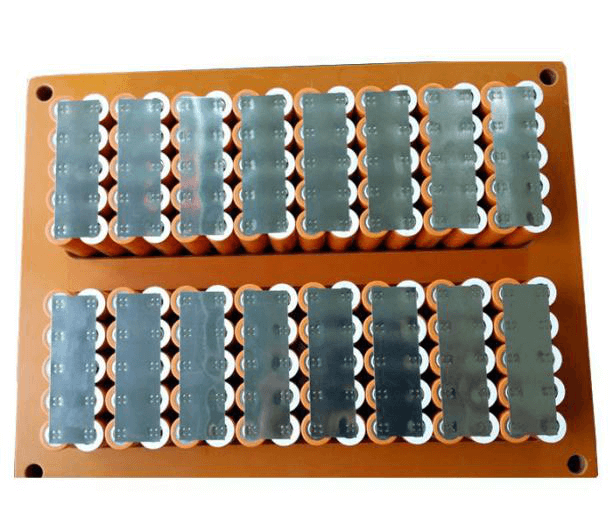

Samples After Automatic Spot Welding Process